ENGINE OVERHAUL

EXCHANGE

If you're short on time, we offer an engine exchange service, allowing you to replace your engine with a fully overhauled one. With a fair trade-in system, it's a faster & more cost-effective way to get back in the air.

BUY PARTS

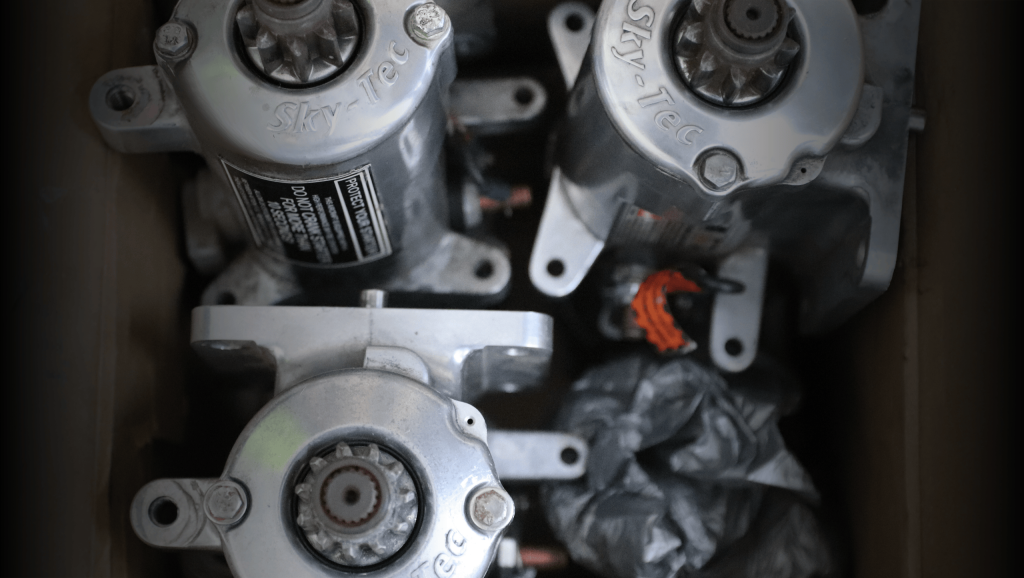

Maintain peak performance with our wide range of OEM engine parts. From new to overhauled and rare components, our e-shop has everything you need. Shop now for top-tier customer service!

BUY AN ENGINE

Buy your aircraft engine now! Choose from new or overhauled options in stock. We recommend Lycoming engines for their proven quality and decades of reliability.

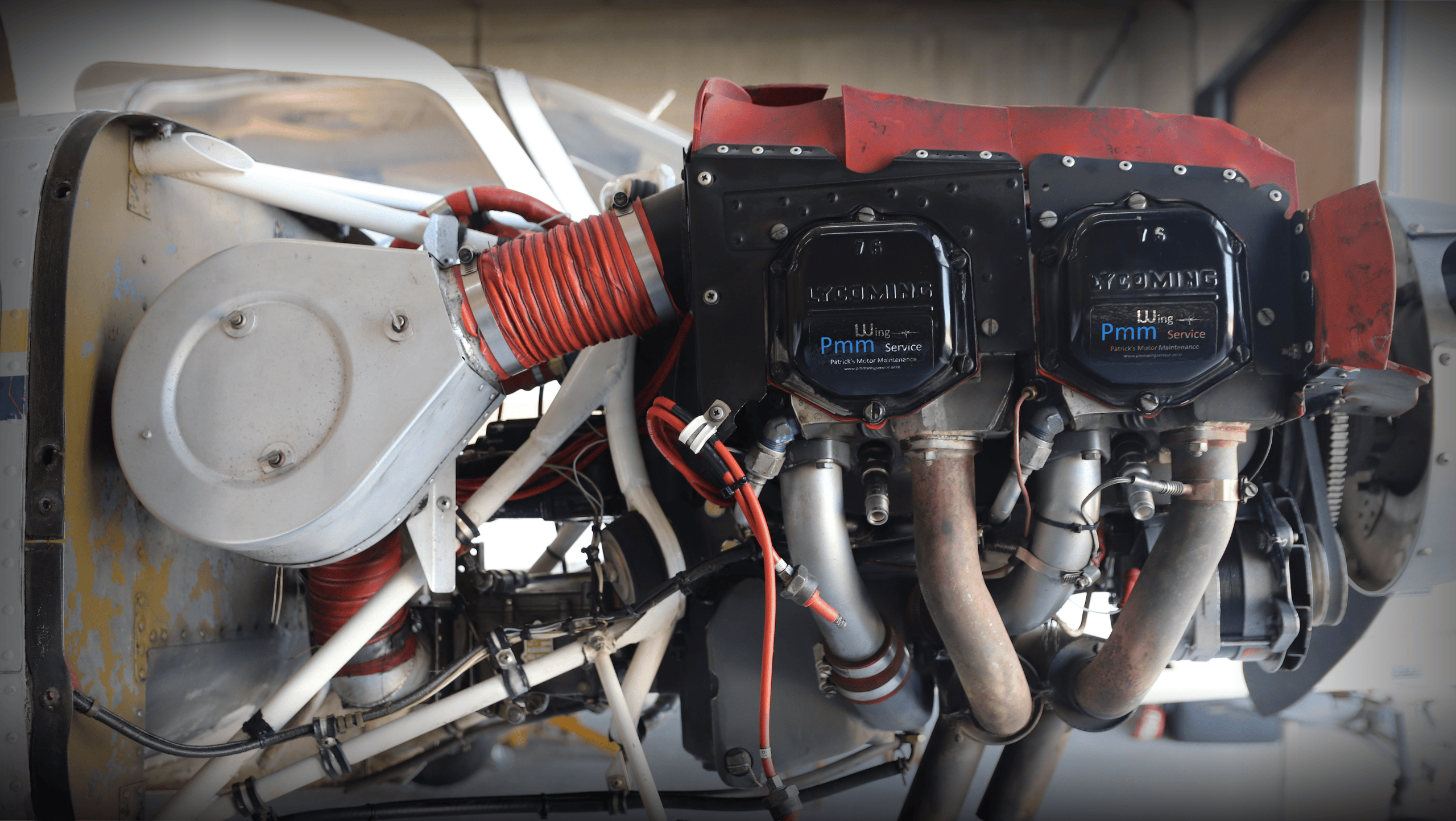

Engine Overhaul

We are experts in Lycoming piston engine overhauls, with our professional team who have been working on these engines for decades with bulletproof results. We have our own in-house non-destructive testing facility with certified experts, as well as a full team of qualified technicians for the best technical support and service as possible. All to be able to provide for our customers the best quality, shorter downtime and the best value.

Lycoming

- O-235 series

- O-320 series

- O-360 / IO-360 series

- IO/TIO-540 series

- All Lycoming Aerobatic engines

We do maintain all normally aspirated or turbocharged, carburetor or injected Lycoming engines.

We work with:

- Aircraft of 5700kg and less (Cessna / Piper)

- We specialize in Lycoming piston engines

- Avionics and electrical systems

- Oil, fuel and brake hoses

- Fuel systems, carburetors/injectors

List of Engines Available for Exchange

Lycoming

► O-235-L2C

► O-235-N2C

► O-320-D2J

► O-320-D3G

► IO-360-L2A

► O-360-F1A6

Custom Tailored Engine Exchange Solutions

We have a large inventory of engines ready to ship or built to order with only a few weeks lead time.

All our overhauled Exchange Engines come with all the mandatory parts as per the latest revision of the manufacturers overhaul manual plus all the NEW or overhauled components. You can schedule everything ahead with us, and become our client, and we will be notifying you for all necessary maintenance in time.

All of our engines in stock are overhauled to manufacturer’s standards with all the mandatory replacement parts required at overhaul. We will supply you with all necessary documentation and paperwork required for the engine’s exploitation in accordance with EASA.

For exchanges, please be advised that if your core, crankcase and or the crankshaft are not serviceable shipment charges back may apply.

Once the engine is disassembled upon completion of the exchange, you will be provided with an update on specs and pricing. Please ensure that all parts with the core engine you provide come with the engine’s removal log book.

Services explained

- Regular Maintenance: 50hr / 100hr / 200hr / Annual inspections

- Perform AD/SB/SEB/SL for Cessna 100/200 series and PA28/44 series

- Airframe / component modification iaw STC

- Airframe and component structural repairs for Cessna / Piper metal structure (MS)

- Avionic installation (PFD/MFD, Nav/Com, XPDR, DME, ELT, Engine monitoring), inflight connectivity, ADSB implementation

- Periodical avionic inspections, Altimeter and pitot-static system inspections

- Major engine maintenance and diagnostics including engine overhaul for all Lycoming piston engines

- Aircraft Import / Export services between CZ and USA (Miami / LA)

- CAMO Management for Cessna / Piper airplanes

Engines described

Lycoming Engines is a major American manufacturer of aircraft engines. With a factory in Williamsport, Pennsylvania, Lycoming produces a line of horizontally opposed, air-cooled, four, six and eight-cylinder engines including the only FAA-certified aerobatic and helicopter piston engines on the market.

The company has built more than 325,000 piston aircraft engines and powers more than half the world’s general aviation fleet, both rotary and fixed wing. Lycoming is an operating division of Avco Corporation, itself a subsidiary of Textron.

Inspired by Charles Lindberg trans-Atlantic flight, Lycoming began developing aviation aircraft engines. Starting in 1929 aviation would never be the same. The first Lycoming R-680, a 9-cylinder 200 hp piston-driven radial engine left the assembly line and established a new standard in general aviation. Lycoming piston engines continue to evolve today as Lycoming continues to develop advanced technologies to remain the power behind general aviation aircraft.

Engine Repairs / Prop Strike /

We’re here to help with any of your Lycoming engine repairs. From a prop strike, metal contamination or corrosion Inspection, to troubleshooting running issues, our experts will help you and get you back into the air. We dedicate our work to quickly determine what the engine needs and provide the best solution to get the engine running again.

Shockload Inspection

Following a propeller strike with damage to the propeller it is imperative that checks are carried out to ensure that engine internal component damage has not occurred. If the engine is run after a propeller strike without these checks having been carried out, further catastrophic damage can destroy the engine, sometimes several hours later.

The following checks are made during a shock load check:

- Propeller shaft, hub and gears NDT tested for cracks and run out

- Gearbox casing in testing for cracks around the main bearing

- Propeller shaft bearings are replaced

- Crankshaft PTO end journal is tested for run out

- Crankshaft magneto flywheel end journal is tested for run out

- Crankshaft phasing checks are carried out

- Woodruff key is checked for distortion and cracks

- Crankshaft woodruff keyway is checked for cracks

- Magneto flywheel is checked for cracks around the hub

- Slipper clutch is checked for correct slipping torque

- All bearings journals replacement and testing

- Crankshaft and camshaft NDT testing and alignment check

- Magneto overhaul

When a slipper clutch is fitted to the engine the crankshaft and flywheel are protected. However, damage may still occur within the gearbox and the first 5 checks in the list are necessary.

Lycoming

- O-235 series

- O-320 series

- O-360 / IO-360 series

- IO/TIO-540 series

- All Lycoming Aerobatic engines

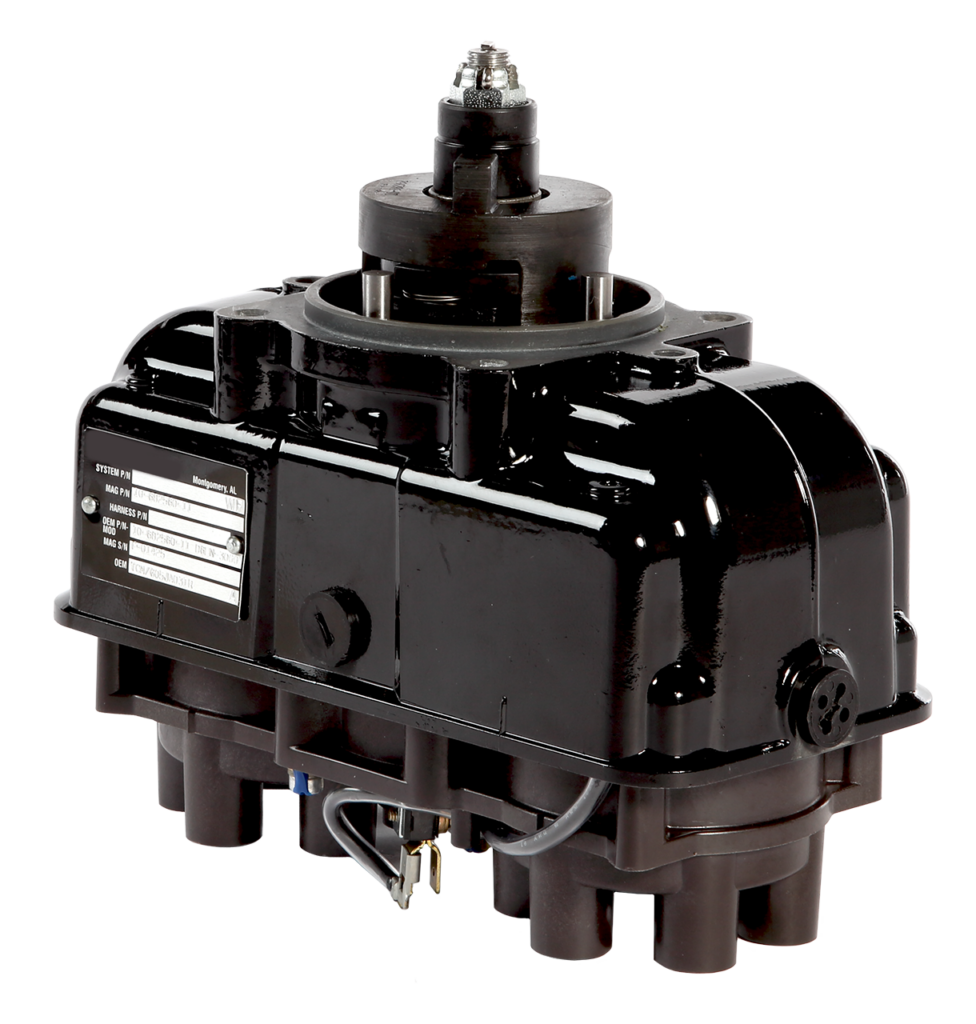

AIRCRAFT MAGNETO OVERHAULS

FOR SLICK, BENDIX, & CONTINENTAL (CMI FMR. TCM) MAGNETOS

Experts in producing FAA/PMA compliant magneto replacement and overhauling services, Falcon Technics is excited to provide services tailored for general aviation. This new offering includes enhancements in coil, capacitor, breaker points, and impulse coupling, establishing the Falcon Technics Magneto servicing as the top-quality choice in the General Aviation sector.

SLICK 4300 & 6300 SERIES AIRCRAFT MAGNETO

The Slick magneto series includes both non-impulse and impulse-coupled units, available for both 4 and 6 cylinders. We offer a comprehensive range of PMA replacement parts, overhaul services, and the ability to perform 500-hour inspections.

BENDIX, CONTINENTAL (CMI)

20 & 200 SERIES

AIRCRAFT MAGNETO

The Bendix, CMI (formerly TCM) 20 series magnetos exclusively feature impulse coupling, while the 200 series magnetos include the “Shower of Sparks” system for both 4 and 6 cylinders. A comprehensive range of PMA replacement components, overhaul services, and 500-hour inspection capabilities are available.

BENDIX, CMI 1200 SERIES

AIRCRAFT MAGNETO

The Bendix CMI (formerly TCM) 1200 series magnetos are available in either impulse-coupled or “Shower of Sparks” configurations for both 4 and 6 cylinder engines. A comprehensive range of PMA replacement engine components, overhaul services, and 500-hour inspection capabilities are offered.

BENDIX D2000/D3000 SERIES MAG

Kelly Aero stands as the sole Original Equipment Manufacturer (OEM) offering freshly manufactured and service components for D2000/D3000 magnetos, which are commonly found on numerous Lycoming engines. Our reconditioned magnetos uphold superior quality, integrating a blend of new components within FAA/PMA approved housing designed for the D2000/D3000 magneto. Kelly takes pride in its commitment to supporting 25,000 engine owners equipped with the Dual magneto, delivering a magneto featuring numerous key enhancements compared to the original D2000/D3000 magnetos.

These enhancements include:

- Adoption of an all-aluminum frame, replacing problematic magnesium frames. The aluminum frame boasts increased strength, durability, and a significantly reduced likelihood of cracking or corroding compared to the original magnesium frames.

- Introduction of an entirely new distributor block and gears, with thousands of these components installed and accumulating tens of thousands of flight hours over the past two decades.

- Incorporation of all-new coils, condensers, and contact points.

REQUEST A QUOTE

We appreciate the chance to address your avionic requirements and offer customized solutions. To get in touch:

Our specialists will contact you for details and clarification. We’ll be glad to help you find the service that best suits you!